Solar battery backup

The WOWsolar line of products provide Pay-As-You-Go power for off-the-grid families in emerging markets.

These products provide home lighting and cell phone charging for those parts of the world living on four dollars or less a day. Over time, users simply add solar panels and battery packs to climb the energy ladder.

Driven Innovation has worked side by side with the team at Amped on numerous innovative products. The Driven Team provides Industrial Design, Mechanical Design / engineering, light pipe design, CAD structural simulation, and production DFM.

Product assembly

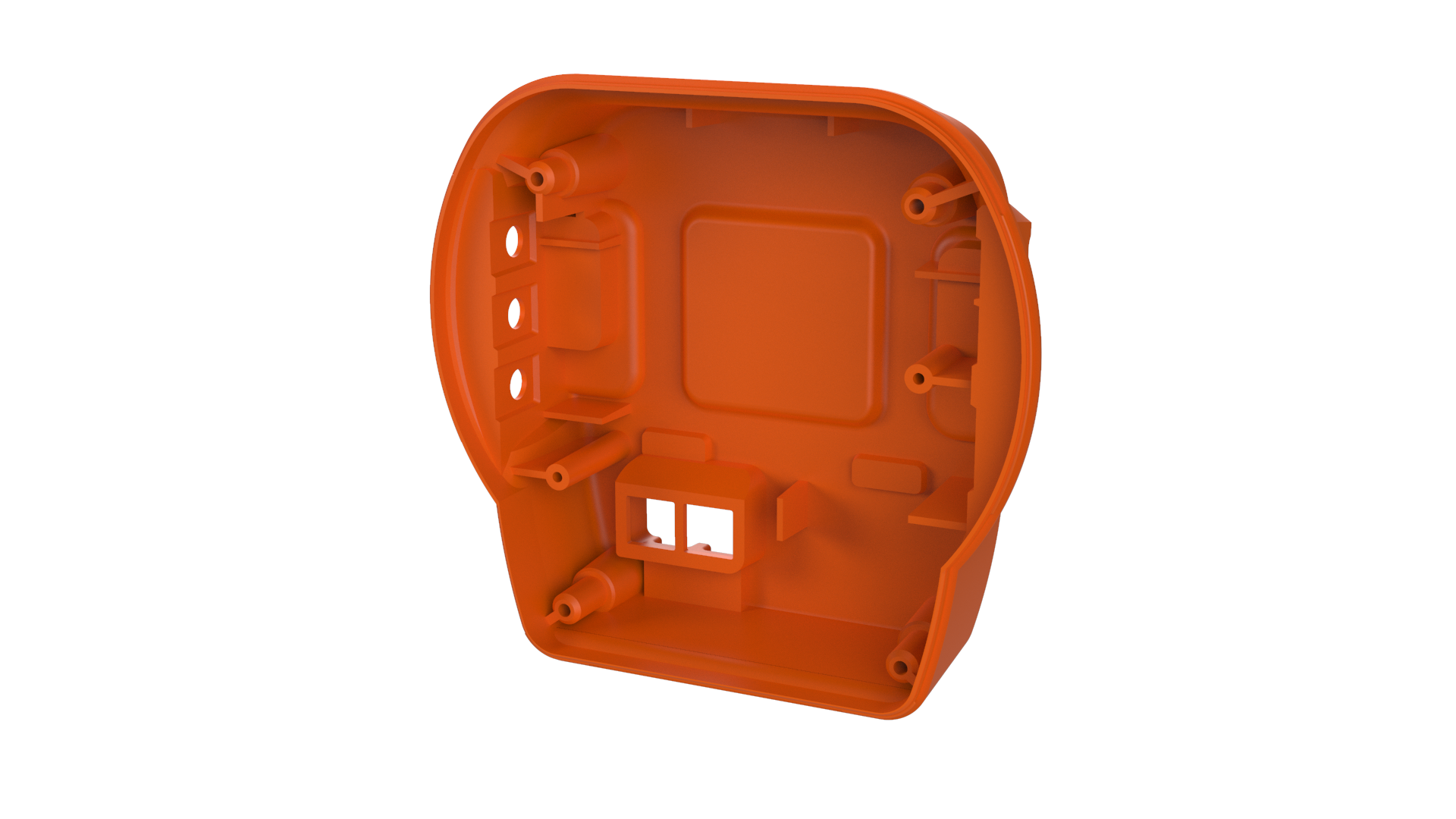

The main product housing consists of two injection molded parts. All internal components are loaded into the bottom housing and the front housing is secured from the back.

Housing textures

High gloss surfaces are used as contrast to the light body texture and to accentuate the front control surface.

Inputs / bracket

The main housing locks onto the wall bracket. All external connectors were grouped together on the sides and positioned underneath the round overhang feature.

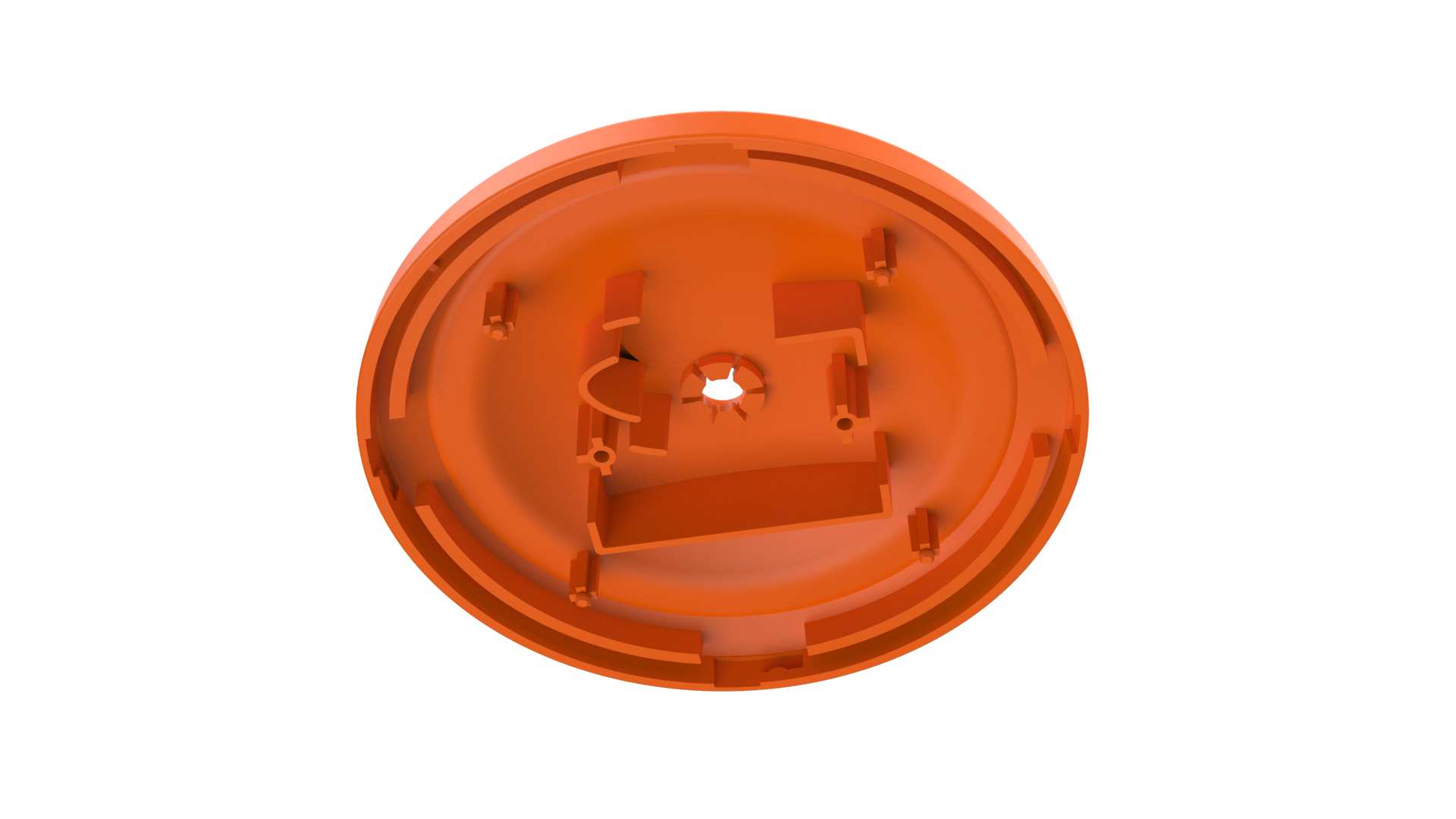

The external lights utilize a translucent domed lens to create an even, diffused light.

The top housing and lens snap together. The PCB uses two screws and four pins to locate and attach to the top housing.

The main housing has numerous internal features to hold the components and to allow external access to connectors.

The Driven team designed and engineered a light pipe that combined pipes for three LED with a seven segment light pipe. This was a highly cost effective and compact solution for a compact and elegant user interface.

The WOWsolar™ Hub